Models: 30HPEP 270 - 30HPEP 250 - 30HPEP 225 - 30HPEP 180

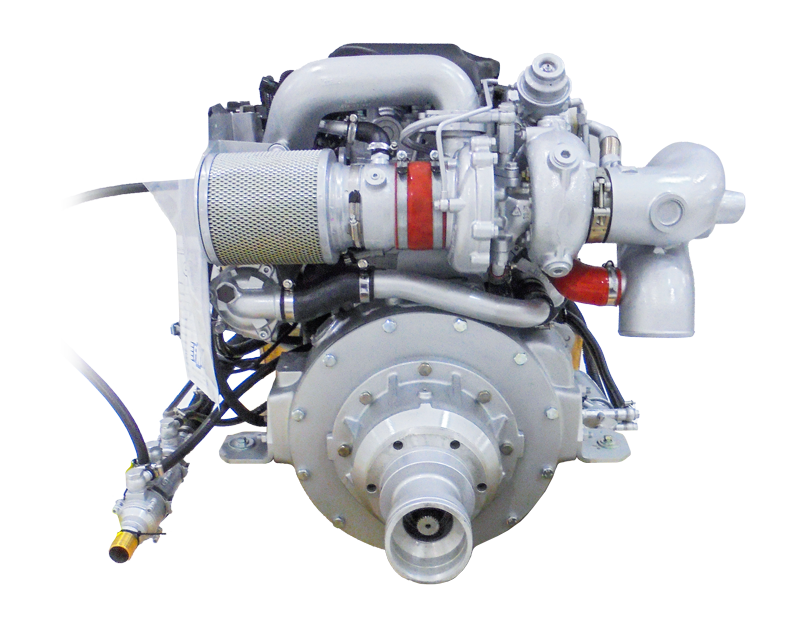

FNM® 30HPEP engine is based on the tested FPT 30 4-cylinder Common Rail engine.

This marine engine uses a common-rail fuel injection system controlled by an ECU specifically made for it. The result is a high power-to-displacement ratio unit.

The engine electronic control unit (ECU) has been conceived after a 10-year development project carried out by R&D team and it is especially designed for HPE marine engines application.

This unit ensures high perfomances in each operating condition:

FOR NAUTICAL PURPOSE

The engine reaches up to 184kW (250HP)

FOR COMMERCIAL PURPOSE

The engine can achieve up to 3000h/year

Engine model

30 HPEP 270

30 HPEP 250

30 HPEP 225

30 HPEP 180

Max power

198,5 kW

270 HP

4100 rpm

184 kW

250 HP

4100 rpm

165 kW

225 HP

4100 rpm

132 kW

180 HP

3800 rpm

Max Torque

530 Nm

2300 rpm

553 Nm

2600 rpm

520 Nm

2300 rpm

N.D.

Number of cylinders

4 in line

Displacement [I] - (cc)

330

Cooling

Water

Combustion

Direct Injection Common Rail

Induction

Turbocharged and itercooled

Engine block and head

Cylinder block made of cast-iron

Cylinder head made of aluminium

Double overhead camshafts

Automotive-class availability of service and parts

Metal chain gear

Engine mounting

Flexible engine mounting

Lubrification system

Easily replaceable oil filter, on top of engine

Double oil vapour filter technology

Integrated cooler with engine's coolant

Fuel system

Common rail fuel injection system

CMD proprietary ECU

Fuel filter with water separator and alarm

Air inlet and exhaust system

Commercial-grade air filter

Oil vapours vented into inlet air

Exhaust elbow or raiser depending on application

Coolant-cooled turbocharger

Raw-water cooled intercooler

Cooling system

Thermostatically regulated freshwater cooling

Easily accessible seawater impeller pump

Electrical system

12V standard two-pole electrical system

Emergency stop button on engine's ECU

CANBUS Panel with 8m extension and digital display of engine data

Panel Instrument high brightness 5 “TFT display, with touchscreen and a very simple and intuitive interface.

Engine data acquisition with CANBUS J1939 interface.

Data acquisition from traditional sensors for up to eight analog inputs, five digital inputs and one frequency input

Acquisition of navigation data with NMEA0183 interface

Up to five relay command outputs for signals and simple activations

Alarm monitoring according to approved safety standards

Automatic brightness adjustment and day / night mode

USB local connectivity for firmware update and configuration

The unit is supplied already programmed and ready to work.

Boiler kit for heating

Various length panel extension

Second control panel for flybridge installations

RACOR and Mediterraneo filters

Trolling Valve

Additional PTO (ISO4183 Z/SPZ)

Steering pump

NMEA2000 compatibility kit